What are the key regulations governing stack emissions in oil and gas operations?

The regulatory framework governing stack emissions in the UK oil and gas industry centres on the Environmental Permitting Regulations (EPR) 2016 and the Industrial Emissions Directive. These regulations mandate that operators monitor and report emissions from all combustion sources, including flares, heaters and power generation units.

Under EPR requirements, facilities must demonstrate compliance with emission limit values through regular stack testing. The Environment Agency requires most large installations to use MCERTS-certified monitoring systems and accredited testing organisations. MCERTS (Monitoring Certification Scheme) ensures that all measurements meet stringent quality standards, providing regulators with reliable data for compliance assessment.

The Medium Combustion Plant Directive has added another layer of complexity, requiring operators to monitor emissions from equipment rated between 1-50MW. This affects numerous installations across oil and gas facilities, from auxiliary boilers to emergency generators.

How does MCERTS certification impact stack emissions monitoring requirements?

MCERTS certification represents the gold standard for emissions monitoring in the UK. The scheme covers three main areas: monitoring systems, testing organisations and personnel competency. For stack emissions testing, this means using certified continuous emissions monitoring systems (CEMS) and engaging accredited testing companies with Level 2 qualified team leaders.

The certification process ensures that monitoring equipment meets performance criteria outlined in European standards EN 15267-1 to EN 15267-4. These standards specify accuracy requirements, calibration procedures and quality assurance protocols that monitoring systems must achieve before certification.

Personnel conducting stack emissions testing must hold MCERTS Level 2 status with appropriate technical endorsements. This includes competency in sampling techniques, equipment calibration and data interpretation. The scheme has recently updated requirements for offshore work in the oil and gas industry, recognising the unique challenges of maritime operations.

Which pollutants require monitoring in oil and gas stack emissions?

Oil and gas operations generate a complex mix of pollutants that require careful monitoring. Primary concerns include nitrogen oxides (NOx), sulphur dioxide (SO2), carbon monoxide (CO) and particulate matter. However, the specific monitoring requirements depend on the type of operation and fuel composition.

Combustion sources typically require monitoring for criteria pollutants including NOx, SO2, CO and total hydrocarbons. Particulate matter monitoring becomes particularly important for facilities using heavier fuel oils or experiencing incomplete combustion. Some installations may also need to monitor for hydrogen sulphide, especially those processing sour gas or crude oil.

Volatile organic compounds (VOCs) present another monitoring challenge, particularly from storage tanks, loading operations and process vents. The Environment Agency increasingly requires VOC monitoring where operations have the potential to impact local air quality. Advanced techniques like Fourier Transform Infrared (FTIR) spectroscopy can simultaneously measure multiple compounds, making monitoring more efficient.

How often must oil and gas operators conduct stack emissions testing?

Testing frequency varies based on the installation’s environmental permit and the specific emission sources involved. Large combustion plants typically require annual testing for most parameters, though some pollutants may need more frequent monitoring. The Environment Agency considers factors like emission levels, plant capacity and environmental sensitivity when setting testing frequencies.

Continuous emissions monitoring systems provide real-time data for key parameters, but these systems still require periodic calibration through manual testing. Annual QAL2 and AST tests verify CEMS performance according to EN 14181 standards. These calibrations ensure ongoing accuracy and compliance with permit conditions.

New installations or those undergoing significant modifications often face more intensive monitoring requirements during commissioning. This may include monthly testing for the first year of operation to establish baseline performance and verify emission control effectiveness.

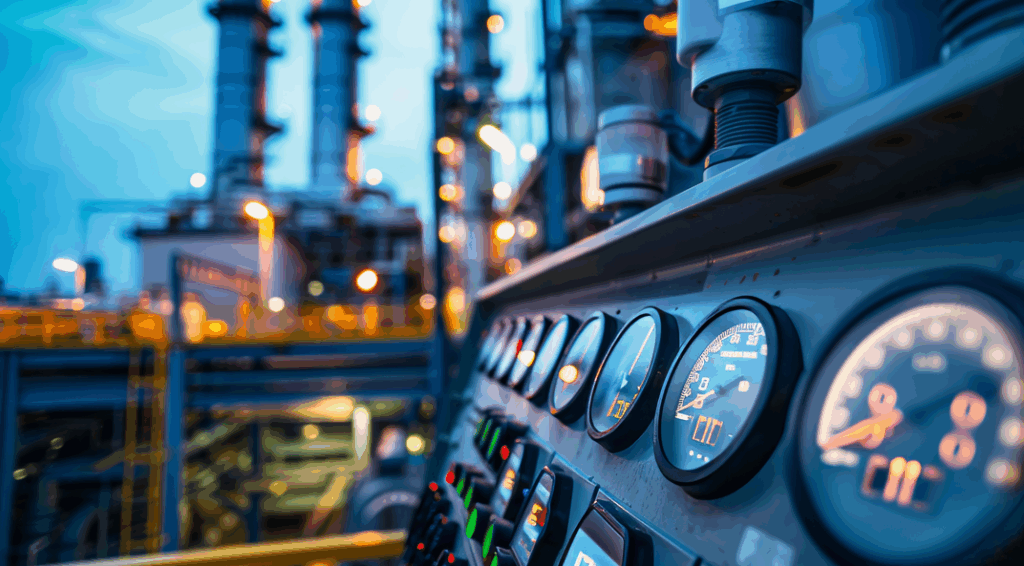

Modern energy infrastructure requires sophisticated monitoring approaches that balance regulatory compliance with operational efficiency.

What challenges do offshore installations face with stack emissions monitoring?

Offshore oil and gas platforms present unique challenges for stack emissions monitoring. Weather conditions, limited access and safety considerations all complicate testing activities. The MCERTS scheme now includes specific provisions for personnel working in offshore environments, recognising these additional complexities.

Logistical challenges include transporting monitoring equipment and analytical samples to and from offshore installations. Weather windows may limit testing opportunities, potentially affecting compliance schedules. Operators must plan testing campaigns carefully, considering regulatory deadlines and operational constraints.

Safety considerations take precedence in offshore environments. Testing teams require additional safety training and equipment beyond standard MCERTS qualifications. Helicopter transfers, confined space entry and working at height all add complexity to emissions monitoring campaigns.

How can operators prepare for stack emissions testing programmes?

Successful emissions monitoring requires thorough preparation and planning. Operators should begin by reviewing their environmental permits to understand specific monitoring requirements and testing frequencies. This includes identifying all emission points that require testing and determining appropriate monitoring methods.

Pre-testing activities include ensuring safe access to all monitoring locations and verifying that sampling ports meet standard requirements. Stack testing requires representative sampling points located away from flow disturbances and at adequate distances from stack outlets. Operators should address any access or safety issues well before scheduled testing dates.

Coordination with accredited testing organisations is essential. Testing companies need detailed information about plant operations, emission sources and expected pollutant concentrations. This enables proper equipment selection and sampling methodology development. Early engagement helps ensure testing schedules align with operational requirements and permit deadlines.

Comprehensive environmental due diligence processes help identify potential compliance gaps before they become regulatory issues.

What role does technology play in modern emissions monitoring?

Technology continues to transform stack emissions monitoring in the oil and gas sector. Advanced CEMS systems now offer multi-component analysis, reduced maintenance requirements and improved data quality. These systems integrate with plant control systems, enabling real-time emission optimisation and early warning of potential excursions.

Remote monitoring capabilities allow operators to access emission data from anywhere, supporting rapid response to changing conditions. Cloud-based data management systems enable sophisticated trend analysis and predictive maintenance of monitoring equipment. These technologies help operators maintain compliance while reducing monitoring costs.

Portable analysers certified under MCERTS now rival fixed systems for accuracy and reliability. These transportable systems enable cost-effective monitoring of multiple emission points and can serve as backup systems during fixed equipment maintenance. Some portable systems incorporate artificial intelligence for automated quality assurance and data validation.

How do emissions testing results influence operational decisions?

Stack emissions testing provides critical data for operational decision-making beyond regulatory compliance. Testing results help operators optimise combustion efficiency, reducing emissions and fuel costs. Regular monitoring can identify equipment degradation before it leads to permit excursions or operational problems.

Emission trends may indicate the need for equipment maintenance or operational adjustments. For example, increasing NOx levels might suggest burner tuning requirements, costs that addressing proactively prevents more serious issues. CO emissions often indicate incomplete combustion, which wastes fuel and may signal safety concerns.

Testing data supports environmental management systems and sustainability reporting. Many operators use emissions monitoring to track progress towards carbon reduction targets and demonstrate environmental stewardship to stakeholders. This information becomes increasingly important as investors and regulators focus on environmental, social, and governance (ESG) performance.

The integration of low carbon environmental design consultants into project planning ensures emissions considerations are embedded from the earliest design stages.

What future trends will shape stack emissions monitoring in oil and gas?

Several trends are reshaping emissions monitoring in the oil and gas sector. Stricter emission limits and expanded monitoring requirements continue to drive regulatory evolution. The UK’s Net Zero commitment will likely influence future monitoring obligations, particularly for CO2 emissions from oil and gas operations.

Digitalisation and data analytics are transforming how operators manage emissions monitoring. Artificial intelligence and machine learning algorithms can predict equipment performance, optimise sampling schedules and identify anomalies in real-time. These technologies promise more efficient monitoring with enhanced compliance assurance.

Satellite monitoring represents an emerging technology for large-scale emission detection. While unsuitable for permit compliance, satellite data can identify emission hotspots and verify ground-based monitoring systems. This technology may complement traditional stack testing, particularly for leak detection and fugitive emissions.

Environmental justice considerations increasingly influence monitoring requirements. Communities near oil and gas facilities demand greater transparency and accountability regarding air quality impacts. This trend may drive more comprehensive monitoring and public reporting requirements.

Climate change adaptation requirements may also affect future monitoring obligations. As extreme weather events become more frequent, monitoring systems must demonstrate resilience and reliability under challenging conditions. This includes backup power systems, weatherproof equipment, and alternative monitoring approaches during emergencies.

Working with experienced sustainable design engineering specialists ensures that emissions monitoring systems are built to meet both current requirements and future challenges.

Stack emissions testing remains fundamental to environmental compliance in the UK’s oil and gas industry. The regulatory landscape continues evolving, driven by climate commitments and public health concerns. Operators who invest in robust monitoring programmes, embrace new technologies and maintain proactive compliance strategies will be best positioned for long-term success.

The complexity of modern emissions monitoring requires expertise across multiple disciplines, from engineering and environmental science to data management and regulatory affairs. By partnering with experienced consultants and investing in quality monitoring systems, oil and gas operators can achieve reliable compliance while supporting broader sustainability objectives.

Ready to enhance your emissions monitoring strategy? Contact Waldeck’s environmental compliance specialists to discuss how we can support your stack emissions testing requirements and help navigate the evolving regulatory landscape.