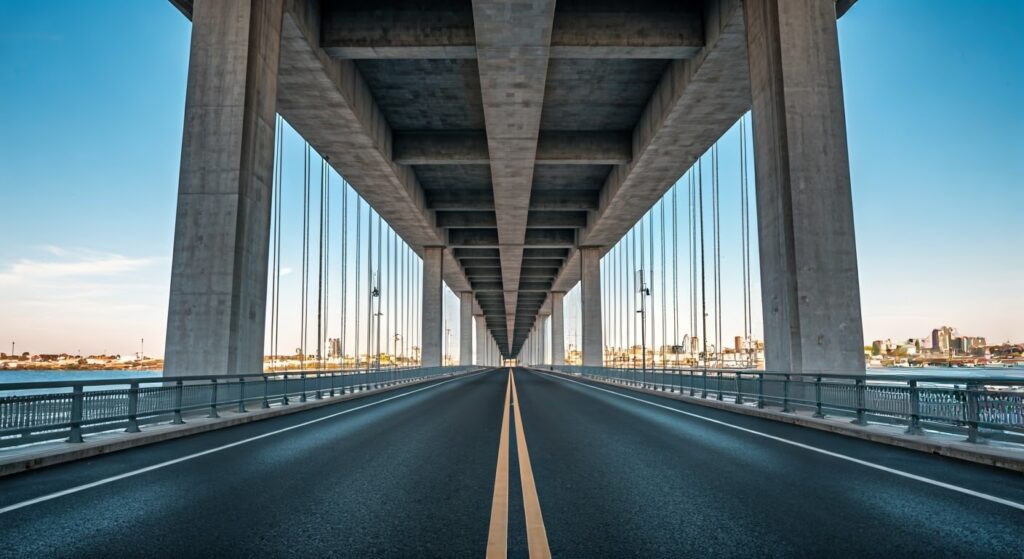

The manual covers various aspects of bridge construction, including deck types, waterproofing and structural requirements.

Engineers working on bridge projects in the UK must adhere to these standards to create structures that can withstand heavy traffic loads and environmental factors.

The manual addresses different bridge types, such as concrete bridges and accommodation bridges, ensuring that each design meets specific criteria for its intended use.

British Standards for bridge design are regularly updated to incorporate new technologies and best practices. This ongoing revision process helps maintain the UK’s reputation for building safe and efficient transport infrastructure.

Engineers and designers can access resources and consultancy services to stay current with the latest standards and apply them effectively in their projects.

Historical Context of British Bridge Design

British bridge design has a rich history spanning centuries. Early bridges were simple wooden structures, later replaced by stone arches.

The Industrial Revolution brought significant changes to bridge engineering.

Iron and steel became popular bridge materials in the 18th and 19th centuries. Engineers like Thomas Telford pioneered new designs, including Scotland’s 45-metre flat arch Craigellachie Bridge.

Historical documents played a crucial role in the evolution of bridge design. Early handbooks and manuals guided engineers, though standards were not yet formalised.

Classifications of details emerged as bridge types diversified. Engineers categorised structures by material, span length and load-bearing capacity. This system helped streamline design processes.

Reinforced concrete became a popular bridge material in the 20th century. However, early designs lacked standardised criteria, leading to durability issues in some structures.

British Standards for bridge design developed gradually. They aimed to ensure safety, efficiency and consistency across projects. These standards evolved with advances in materials and engineering knowledge.

By 2010, a significant shift occurred. Eurocodes replaced British Standards as the main design standards for UK bridges. This change aligned British practice with European norms.

Overview of British Standards for Bridges

British Standards are crucial in ensuring the safety and quality of bridge design and construction. The Design Manual for Roads and Bridges (DMRB) is the primary reference for bridge engineers in the UK.

The DMRB contains comprehensive standards and guidelines for all road and bridge design aspects. It covers topics such as:

- Structural requirements

- Loading calculations

- Material specifications

- Durability considerations

- Safety measures

Bridge designers must adhere to the DMRB standards to ensure their projects meet regulatory requirements.

These standards are regularly updated to reflect advances in engineering knowledge and practices.

The Standards for Highways organisation maintains and publishes the DMRB. They work closely with industry experts to develop and refine the standards.

Key elements of British bridge design standards include:

- Structural integrity

- Serviceability

- Durability

- Sustainability

- Aesthetic considerations

Engineers can create safe, functional and long-lasting bridges by following these standards. The DMRB provides a solid foundation for bridge design in the UK, ensuring consistency and quality across projects.

Legislative Framework

The United Kingdom has a robust system for bridge design standards. These standards ensure safety and consistency across the country’s infrastructure projects.

The Design Manual for Roads and Bridges (DMRB) is a key document in this framework. It provides comprehensive guidance for highway structures, including bridges.

Alongside the DMRB, the Manual of Contract Documents for Highway Works (MCHW) plays a crucial role. The MCHW outlines contractual and technical requirements for highway projects.

These documents work together to create a solid legislative foundation. They cover everything from initial design to construction and maintenance.

Critical aspects of the legislative framework include:

- Safety regulations

- Environmental considerations

- Accessibility requirements

- Material specifications

Engineers and contractors must adhere to these standards. Failure to do so can result in project delays or legal consequences.

The framework is regularly updated to reflect new technologies and best practices, ensuring that UK bridge design remains at the forefront of innovation and safety.

The Design Manual for Roads and Bridges

The Design Manual for Roads and Bridges (DMRB) is crucial for UK road and bridge design. It provides comprehensive standards and specifications for engineers and designers working on motorways and trunk roads.

Importance in Design Specification

The DMRB contains current design standards for UK motorway and trunk road projects.

It covers various topics, including materials, workmanship and design requirements. Engineers rely on the DMRB to ensure their designs meet safety and quality standards.

The manual is regularly updated to reflect new technologies and best practices, helping maintain the highest road and bridge construction standards.

The DMRB also includes guidance on assessment and operation, making it valuable throughout a project’s lifecycle.

For bridge design, the DMRB provides specific requirements. These cover aspects like waterproofing and surfacing of concrete decks. Such details are critical for ensuring the longevity and safety of bridge structures.

Using the DMRB Website

The DMRB website is a key tool for accessing up-to-date standards.

It offers a user-friendly interface for designers to find relevant information quickly. The site includes a search function to locate specific standards or topics.

Users can access both current and older versions of standards.

This feature is helpful for ongoing projects that may reference previous versions. The website also provides an index of all published documents, making it easy to navigate the extensive collection.

Regular updates to the website ensure that users always have access to the latest standards. This helps maintain consistency and quality across different projects.

Feedback and Communications

The DMRB team actively seeks input from industry professionals. This helps improve the manual and keep it relevant.

Users can send feedback on DMRB documents to a dedicated email address.

National Highways manages the DMRB and communicates updates and changes through the website. They also guide the implementation of new standards.

This open communication helps ensure that all stakeholders are aware of current requirements.

The feedback process allows for continuous improvement of the DMRB. It ensures that the manual remains a valuable and up-to-date resource for the industry.

Material Specifications and Standards

British Standards guide the use of materials in bridge construction. These standards ensure safety, durability and performance. They cover steel, concrete and composite materials used in modern bridges.

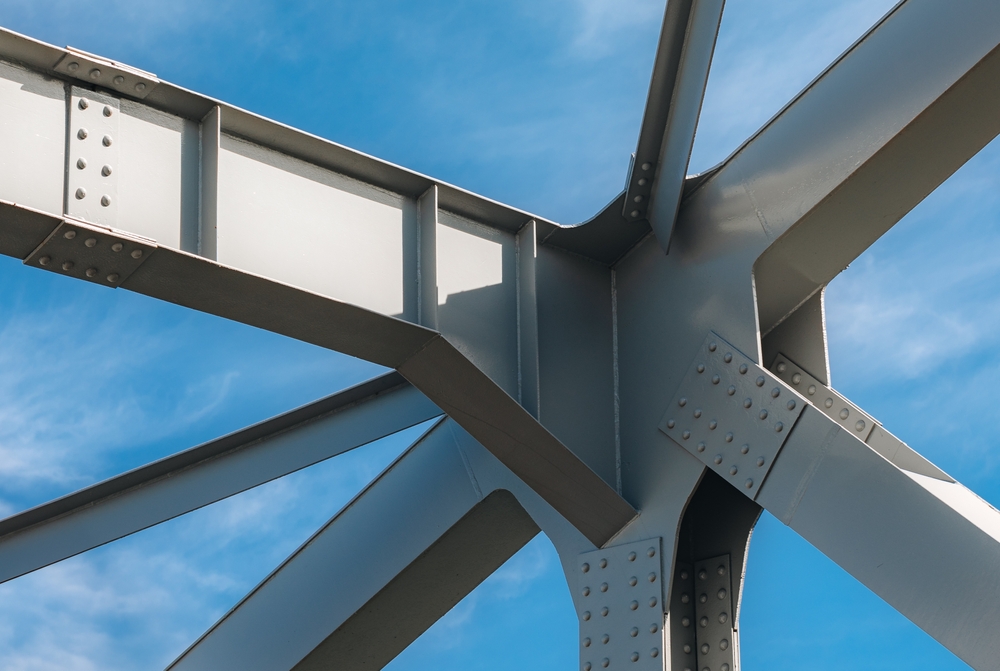

Steel in Bridge Construction

Steel plays a crucial role in bridge design. British Standards for steel in bridges set strict requirements.

These include strength, toughness and corrosion resistance.

Steel grades like S355 and S460 are common in bridge construction. They offer high strength-to-weight ratios, allowing for longer spans and slimmer designs.

Welding standards are crucial for steel bridges. They ensure joints can handle stress and fatigue. Regular inspections check for cracks or rust.

Protective coatings extend the life of steel bridges. These must meet British Standards for durability and environmental safety.

Concrete in Bridge Construction

Concrete is vital in bridge building. British Standards specify mix designs, strength classes and durability requirements.

Key elements, such as bridge decks and support columns, are often made of high-strength concrete, often above 50 MPa.

Additives improve concrete properties. These may boost strength or reduce water content. All must comply with British Standards.

Reinforced and pre-stressed concrete are common in bridges. Standards cover steel reinforcement placement and tensioning methods.

Testing is critical to ensuring concrete quality. This includes slump tests, cube strength tests and durability assessments.

Advances in Composite Bridges

Composite bridges blend steel and concrete benefits. They’re gaining popularity in the UK.

Fibre-reinforced polymers (FRPs) are new in bridge design. They offer high strength and low weight. British Standards are evolving to cover their use.

Carbon fibre composites are used in some bridge elements. They resist corrosion better than steel, which can lower maintenance costs.

Composite decks often use steel beams with concrete slabs. This creates a strong, lightweight structure.

British Standards now include guidelines for composite bridge design. These cover material properties, load calculations and long-term performance.

Bridge Design Considerations

Bridge design in the UK involves careful planning to meet safety standards and performance requirements. Engineers must account for various factors when developing bridge designs.

Highway and Motorway Context

Bridges on highways and motorways face unique challenges. Traffic volume and vehicle types influence design choices.

Engineers consider road classifications like all-purpose trunk roads when planning.

Deck width must accommodate lanes and hard shoulders. Clearance heights vary based on expected vehicles. Motorway bridges often need wider decks and higher clearances than local road bridges.

Bridge approaches require careful grading to ensure smooth transitions.

Drainage systems prevent water pooling on decks. Noise barriers may be needed in populated areas.

Load Classifications and Fatigue

Bridges must withstand various loads. Dead loads include the structure’s weight. Meanwhile, live loads come from traffic and environmental factors.

Load capacities are based on expected traffic. Heavy goods vehicles have a significant impact, and wind and temperature changes create additional stresses.

Engineers use load models to simulate long-term effects. This helps them predict how repeated loading can cause material failure over time. Then, they give extra attention to high-stress areas in design and inspection plans.

Code of Practice and Workmanship

UK bridge design follows strict codes of practice. These ensure consistency and safety across projects. The Design Manual for Roads and Bridges (DMRB) is a key reference.

Workmanship standards cover construction quality. This includes concrete mixing, steel fabrication, and welding. Regular inspections verify compliance during building.

Material testing confirms strength and durability; non-destructive testing checks for hidden flaws. Quality control measures continue throughout the bridge’s lifespan.

Design for Steel Bridges

Steel bridges offer strength and span flexibility. Common types include plate girders and box girders. Meanwhile, truss designs suit longer spans.

Corrosion protection is crucial. Painting systems and weathering steel are common solutions. Then, deck systems often combine steel beams with concrete slabs.

Connections also require careful detailing. Bolted and welded joints must effectively transfer loads, and thermal expansion joints allow movement without stress.

Design for Concrete Bridges

Concrete bridges suit various span lengths. Reinforced and prestressed designs are common. Post-tensioning enhances strength in longer spans.

Deck waterproofing prevents water damage. Expansion joints manage thermal movement, and drainage systems protect structural elements.

Concrete mix design balances strength and durability. Admixtures improve workability and frost resistance. Lastly, curing methods ensure proper strength development.

Bridge Bearings and Components

Bridge bearings play a crucial role in bridge design. They connect the deck to the substructure and allow for movement caused by temperature changes, traffic loads and other factors.

The British Standards for bridge bearings include BS EN 1337 and BS 5400. These standards guide bearing design, materials and installation.

Types of bridge bearings include:

- Elastomeric bearings

- Pot bearings

- Spherical bearings

- Roller bearings

Each type has specific uses depending on the bridge design and expected loads.

Bridge designers must consider several factors when selecting bearings:

- Vertical and horizontal loads

- Rotational requirements

- Movement range

- Durability and maintenance needs

The Design Manual for Roads and Bridges also offers guidance on bridge bearing selection and design. This resource is widely used in the UK for highway bridge projects.

Proper installation and maintenance of bridge bearings are essential. Regular inspections help ensure they continue functioning as intended throughout the bridge’s lifespan.

Other important bridge components include:

- Piers

- Abutments

- Deck systems

- Expansion joints

These elements work together with bearings to create a safe and efficient bridge structure.

Maintenance and Inspection

British Standards for bridge design emphasise the importance of regular maintenance and inspection. These practices help ensure the safety and longevity of bridge structures.

Bridge inspections are typically carried out at set intervals. They may include visual checks, structural assessments, and component testing.

Maintenance activities often focus on:

- Cleaning and clearing debris

- Repairing damaged elements

- Replacing worn components

- Treating corrosion

- Updating safety features

Pavements are a crucial part of bridge maintenance. Regular checks help identify issues like cracking, wear or drainage problems.

The Design Manual for Roads and Bridges (DMRB) guides maintenance and inspection procedures. It outlines best practices for UK bridge engineers and maintenance teams.

Proper record-keeping is essential. Detailed logs of inspections and maintenance work help track the bridge’s condition over time.

Advanced technologies are increasingly used in bridge maintenance. These may include:

- Drones for visual inspections

- Sensors for real-time monitoring

- 3D scanning for precise measurements

Structures and Durability

British Standards for bridge design place great emphasis on durability. This focus helps ensure structures last longer and require less maintenance over time.

The Design Manual for Roads and Bridges outlines key durability requirements for highway structures. These standards apply to bridges, retaining walls and abutments.

Designers must consider several factors when planning for durability:

- Environmental conditions

- Material selection

- Construction methods

- Maintenance strategies

One crucial aspect is waterproofing bridge decks. This protects concrete from water and salt damage, extending the structure’s lifespan.

British Standards also address specific types of structures. For example, they guide the design of accommodation bridges and footbridges.

To enhance durability, designers often use advanced materials and techniques. These may include:

- High-performance concrete

- Corrosion-resistant reinforcement

- Protective coatings

Date Filter and Relevance

The Design Manual for Roads and Bridges (DMRB) offers a helpful date filter feature for accessing archived copies of standards. This tool helps engineers and designers find relevant information from specific periods.

Standards evolve to reflect new research, technologies and best practices. The date filter lets users view standards applicable at a particular historical point.

This feature is especially valuable when:

- Assessing older structures

- Reviewing historical design decisions

- Researching the evolution of standards

Ensuring that the most up-to-date standards are used for new designs is crucial. However, accessing older versions provides essential context and historical perspective.

The relevance of standards can vary based on factors such as:

- Project type

- Geographic location

- Specific design requirements

Engineers must carefully consider which standards apply to their projects, using current and historical information as appropriate.

Frequently Asked Questions

BS 5400 is the main standard for concrete bridge design. It covers structural design, materials and construction methods. Parts 1 to 10 of BS 5400 deal with different aspects of bridge engineering. The Design Manual for Roads and Bridges (DMRB) also includes guidelines for concrete bridges. It covers waterproofing and other specific design elements.

Public libraries often provide free access to British Standards. Some universities and professional organisations also offer access to their members. The BSI Group (BSI) website allows the free viewing of standards’ content. However, full downloads usually require payment.

BS 5400 Part 1 covers general statements and design principles. Part 2, on the other hand, deals with loads and loading. Part 3 focuses on steel bridges, while Part 4 covers concrete bridges. Meanwhile, Part 5 addresses composite bridges. Parts 6 to 10 then deal with bearings, foundations and erection procedures.

The BS 5400 series has been replaced mainly by Eurocodes, which provide a common design approach across Europe. The Design Manual for Roads and Bridges also includes updated standards for bridge design. Recent updates focus on sustainability, resilience to climate change, and using new materials.

ISO 13822 provides guidelines for assessing existing structures, including bridges. It complements British Standards. ISO 21931, on the other hand, addresses sustainability in buildings and civil engineering works. This aligns with recent updates to British Standards, which often reference relevant ISO codes to ensure international compatibility.

BS 5400 outlines requirements for loads, materials and structural elements. It specifies safety factors and design methods. The standard covers different bridge types, including concrete, steel and composite structures. It also addresses fatigue, vibration and durability. Bridge design loads are a key consideration. These include traffic, wind and temperature effects.